Top Quality Steel Truck Wheels Shot Blast Machine - Steel Plate Shot Blasting Machine – Binhai Jincheng

Top Quality Steel Truck Wheels Shot Blast Machine - Steel Plate Shot Blasting Machine – Binhai Jincheng Detail:

BH Blasting——Q69 Series Steel Plate Shot Blasting Machine, make your job more efficiency and save your cost

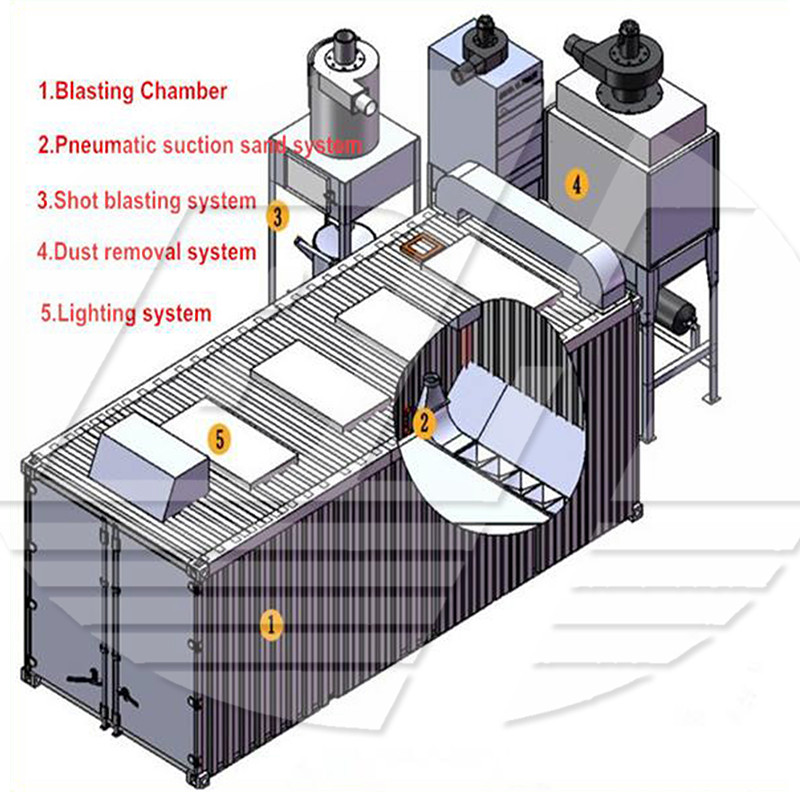

Overview of Steel Plate Shot Blasting Machine

Steel Plate Shot Blasting Machine strongly blast the sheet metal and profiles to remove surface rust, welding slag and scale, making it slow uniform metal color, improve coating quality and corrosion prevention effect. Its processing range from 1000mm to 4500mm, and it can easily integrated intro preservation lines for automatic painting.

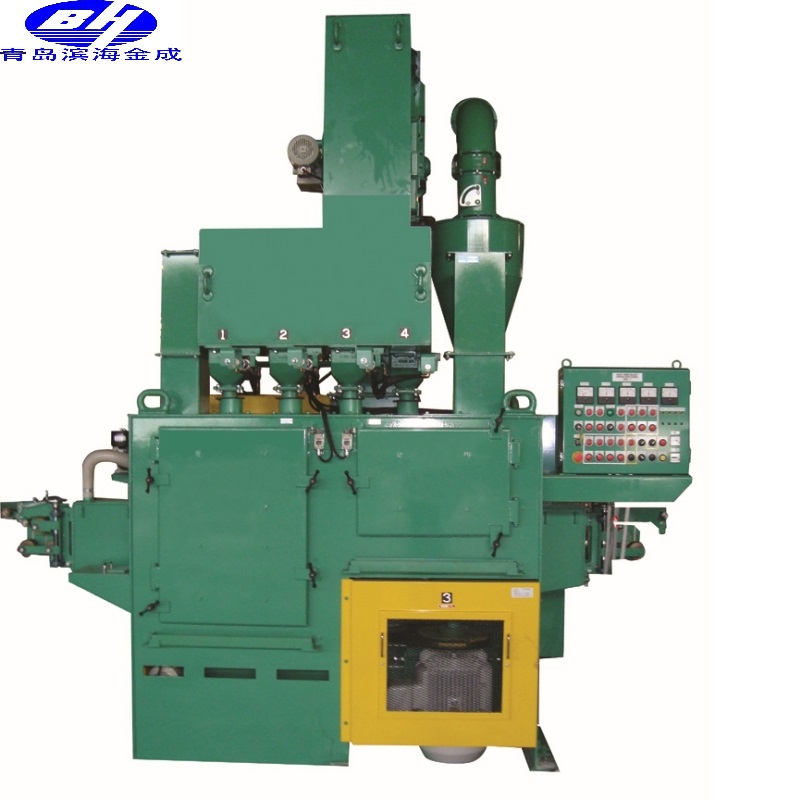

The Details of BH Steel Plate Shot Blasting Machine

This production line consists of feeding roller table, workpiece detection device, shot blasting cleaning, shot material circulation system, cleaning device, chamber roller table, feeding roller table, shot blasting dust removal system, and electric control system.

The workpiece is moved to the feeding roller table by the loading forklift or row crane, and then sent to the closed shot blasting cleaning room by the roller table conveyor system. , Impact on the surface of the workpiece, scrape to remove the rust and dirt on the surface of the workpiece, and then use the roller brush, pill collection screw and high-pressure blow pipe to clean the accumulated particles and floating dust on the surface of the workpiece, and then send it out of the purge chamber by the roller conveyor , Arrive at the delivery roller table, and then transport to the designated unloading rack via forklift or crane.

The Specification of BH Steel Plate Shot Blasting Machine

| Item | Unit | Q698 | Q6912 | Q6915 | Q6920 | Q6930 | Q6940 |

| Effective cleaning width | mm | 800 | 1200 | 1500 | 1800 | 3200 | 4200 |

| Width of feed inlet size | mm | 1000 | 1400 | 1700 | 2000 | ||

| Length of the workpiece | mm | 1200-12000 | 1200-13000 | 1500-13000 | 2000-13000 | ≧2000 | ≧2000 |

| Transmission speed | M/min | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 |

| Shot volume abrasive flow rate | Kg/min | 8*180 | 8*180 | 8*250 | 8*250 | 8*360 | 8*360 |

| The first time loading capacity | kg | 4000 | 5000 | 5000 | 6000 | 8000 | 10000 |

| Ventilation | M³/h | 20000 | 22000 | 25000 | 25000 | 28000 | 38000 |

The Advantages of BH Steel Plate Shot Blasting Machine

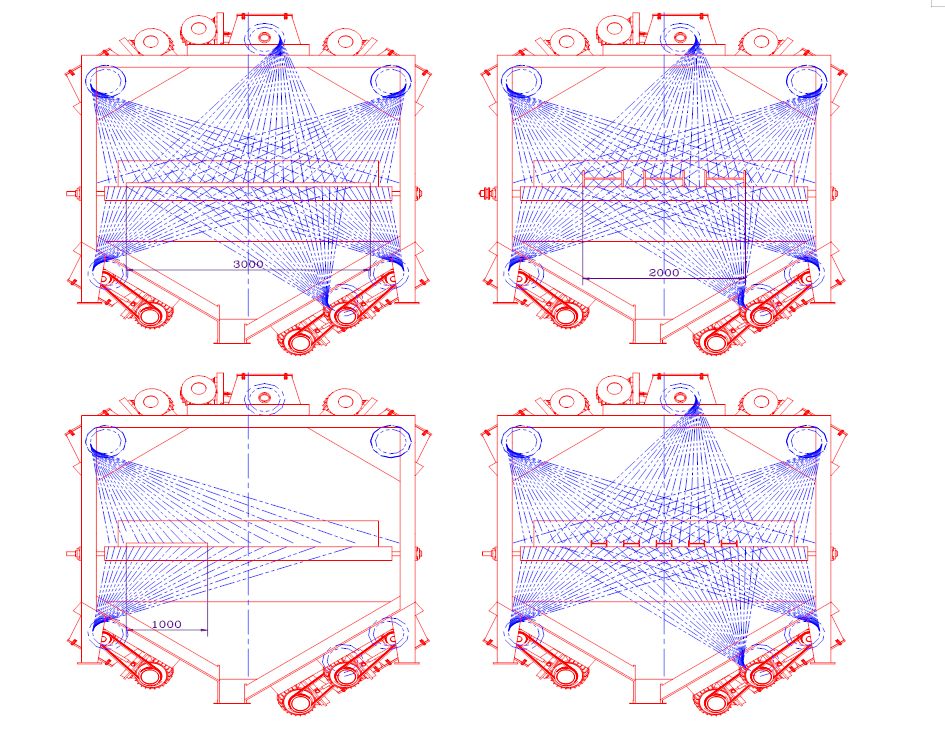

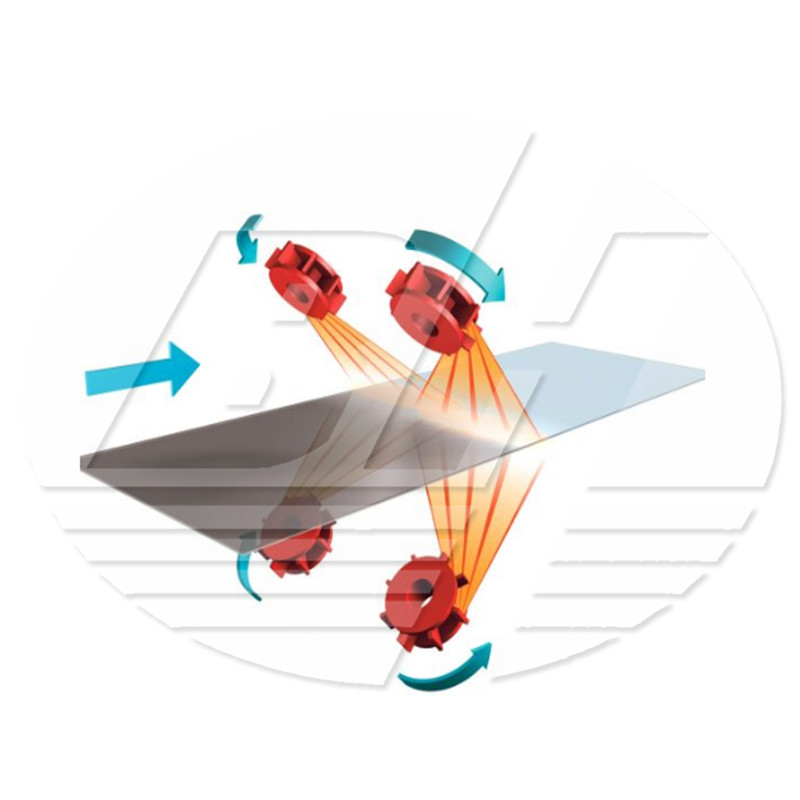

● The shot blaster layout is computer-simulated and arranged in a diamond shape. The upper and lower shot blasters correspond to each other to improve the utilization rate of the abrasive. Make the abrasive coverage uniform.

● Shot blasting Chamber guard plates adopt 8mm thick impact-resistant and wear-resistant 65Mn, and adopts building block installation method. The arrangement of the guard plate more effectively improves the room protection effect. The number of shot blasters can be determined according to the size of the workpiece, which can reduce unnecessary energy waste and reduce unnecessary damage to the equipment.

● Separation device adopts advanced full-curtain flow curtain type slag separator, and the separation efficiency can reach 99.9%

● Workpiece detection device, effectively control the opening and stopping time of the shot blasting machine, avoid the empty emptying of the shot blasting machine, save energy, and improve the life of the wearing parts such as the room guard plate and the shot blasting machine.

● Automatic fault detection and alarm, and automatic stop after delay.

● Dust removal system adopts high-efficiency filter drum dust collector, the dust emission is within 100mg / m3, and the workshop dust emission is within 10mg / m3, which greatly improves the worker’s operating environment.

● The bearing protection at both ends of the elevator, separator, and screw conveyor adopts a labyrinth sealing device and a U-shaped boss structure. The separation screw and screw conveyor discharge ports are arranged at a distance from the end, and at the end of the screw Add reverse conveying blades.

● The hoist adopts special polyester wire core hoist transmission belt, and the upper and lower reels of the hoist adopt chamfered squirrel cage structure, which not only increases friction to avoid slipping, but also prevents scratching of the belt. Each power point of the abrasive circulation system is provided with a fault alarm function.

● The large nut fixed by our company adopts cast special iron nut, its structure and the contact surface of the protective plate are larger, and it is more effective to prevent the broken ring caused by the abrasive entering the shell due to the loosening of the nut.

● abrasive cleaning

In order to meet the requirements of higher production efficiency, we use:

First-level cleaning: high-strength nylon roller brush + pill collecting screw; cleaning brush life ≥5400h

Secondary air blowing: high-pressure fan blows shots and blows dust inside and outside the cleaning chamber to ensure that there are no shots on the surface when the steel plate is cleaned out of the cleaning room.

● Roller drive adopts stepless frequency conversion speed regulation (using frequency converter, the manufacturer is generally Mitsubishi, can also be specified), instead of speed regulation motor, the entire workpiece conveying system frequency conversion stepless speed regulation. (Speed range 0.5-4m / min)

● Input, output and segmented transmission of the chamber roller table, stepless speed regulation, that is, it can run synchronously with the entire line, and can also run quickly, so that the steel can quickly travel to the work position or quickly exit to the discharge station purpose.

● Adopt full line PLC programmable controller power, automatic detection and automatic search for fault point, sound and light alarm.

● The equipment has a compact structure, a reasonable layout, and is very convenient for maintenance.

The Application of Steel Plate Shot Blasting Machine

Steel Plate Shot Blasting Machine is designed based on a roller conveyor and especially developed to meet the needs of the fabrication industry, the range of machines descales and removes rust prior to fabrication. Rolled steel plate, shapes and fabrications are used across a wide range of sectors, from construction to ship building. It provides a better surface for welding and improves coating adhesion. Large sections can be cleaned quickly, saving time and reducing bottlenecks in production.

The Production Process of Steel Plate Shot Blasting Machine

The Drawing of Steel Plate Shot Blasting Machine

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for Top Quality Steel Truck Wheels Shot Blast Machine - Steel Plate Shot Blasting Machine – Binhai Jincheng , The product will supply to all over the world, such as: Latvia, Mexico, Danish, We welcome you to visit our company & factory and our showroom displays various products that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to provide you with the best services. If you need more information, please do not hesitate to contact us via E-mail, fax or telephone.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.