Professional China Shot Blasting Machinery In Abrator - Tumble Belt Shot Blasting Machine – Binhai Jincheng

Professional China Shot Blasting Machinery In Abrator - Tumble Belt Shot Blasting Machine – Binhai Jincheng Detail:

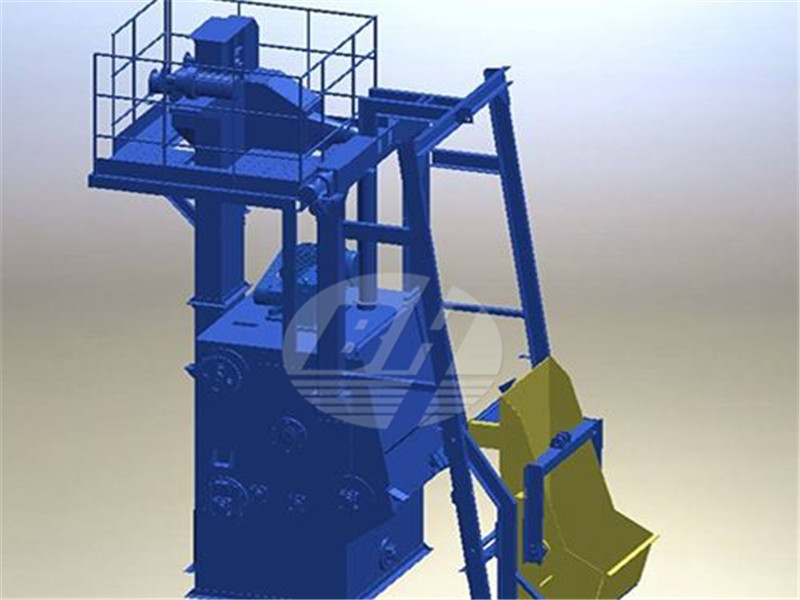

Tumble Belt Shot Blasting Machine

This series machine are suitable for surface cleaning and strengthening of

medium or small size castings

forge pieces

variety of hardware

Metal stamping

And other small size metal workpieces.

For different production capacity, machine can work alone or work together in a line.

Tumble Belt Shot Blasting Machine technical Parameters

|

Item |

Unit |

Q326 |

QR3210 |

QS3215 |

QS3220 |

QLX32320 |

|

Productivity |

kg/h |

600-1200kg/h |

2000-3000kg/h |

4000-5000kg/h |

5000-7000kg/h |

6000-10000kg/h |

|

Number of turbines |

pcs |

1Pcs |

1Pcs |

2Pcs |

2Pcs |

4Pcs |

|

Feeding amount per time |

kg |

200Kg |

600Kg |

1000-1500kg |

1500-2000kg |

800Kg |

|

Maximum weight of single piece |

kg |

15Kg |

30Kg |

50Kg |

60Kg |

50kg |

|

Diameter of end disk |

mm |

Φ650mm |

Φ1000mm |

Φ1000mm |

Φ1200mm |

Φ1000mm |

|

Power of turbine |

kw |

7.5kw |

15kw |

15kw*2 |

18.5kw*2 |

11kw*4 |

|

Abrasive flow rate |

Kg/min |

125Kg/min |

250Kg/min |

250Kg/min*2 |

300Kg/min*2 |

240kg/min*4 |

|

Ventilation capacity |

m³/h |

2200m³/h |

5000m³/h |

11000mm³/h |

15000m³/h |

15000m³/h |

|

Power consumption |

kw |

12.6kw |

28kw |

45kw |

55kw |

85kw |

|

With loading /unloading device |

Without |

With |

With |

With |

With |

Tumble Belt Shot Blasting Machine each part character

1. Blast wheel motor

Use ABB motor or China brand, good sealing, good

dynamic balance, stable and reliable

performance.

2. Blast chamber

Welded with all manganese steel.

The top is equipped with a three-layer sealing structure toprevent the steel shot fromleaking.

wear resistant rubber tracks,with fascia,make the workpiece easy rolling.

3.Turbine

Belt connection centrifugal type blast wheel, more stable and uniform speed. High impeller rotate speed 3000r/min

1.impeller rotation speed is 3000r/min

2.Rejection speed:80m/s,other supplier’s speed only 72-74m/s

3.Inner structure is tight,reliable and low noise

4.Top,side protect board are use special structure, partial thickness is 70mm,with much better wear resistance

5.QBH037 blast wheel use Japan Sinto technical, cantilever centrifugal type,with big impact force,with much more better cleaning and strengthen effect. Can improve 15% work efficiency than other same power blast wheel.

Easy accessibility and easy replacement of the blades

4.Separation system

Air flow separator

With air flow generated by a wind turbine, metal shot is recycled in hopper, crushed shots are expelled from waste pipe, dust is taken to dust-collector.

Pulse bag-type dust collector

Dust collector

Centrifugal fan

Collection Pipe

Two-stage dust collecting mode:

Primary dust collecting,the settling chamber is an aerodynamically inertial settling chamber, which can achieve effective settlement of the projectile without pressure loss.

The secondary dust removal is bag filter. The dust collector is a pulse back flushing system. It has low filtering wind speed, high filtration precision, and good dust-cleaning effect.

6.Control Unit

Using Chint low voltage electrical components.(https://en.chint.com)

Omron PLC (Internnational Brand Q326C type without it)

Machine Advantages

1.More thicker guard board,high wear resisting cast iron

2.with frame more stronger

3.Thicker track, high content gum

4.Uniform speed

5.Small machine vibration

6.Longer life time

7.Especially widely used

8.4-5 levels efficiency for your choose

9.Best wear-resisting protective liner

After cleaning photo

Product detail pictures:

Related Product Guide:

Sticking to the belief of "Creating products of high quality and making friends with people from all over the world", we always put the interest of customers in the first place for Professional China Shot Blasting Machinery In Abrator - Tumble Belt Shot Blasting Machine – Binhai Jincheng , The product will supply to all over the world, such as: Italy, Nepal, Seattle, Our mission is to deliver consistently superior value to our customers and their clients. This commitment permeates everything we do, driving us to continuously develop and improve our products and the processes to fulfill your needs.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!