One of Hottest for Hot Selling Abrator Turn Table Shot Blasting Cleaning Equipment Machine - Tunnel type shot blasting machine profile – Binhai Jincheng

One of Hottest for Hot Selling Abrator Turn Table Shot Blasting Cleaning Equipment Machine - Tunnel type shot blasting machine profile – Binhai Jincheng Detail:

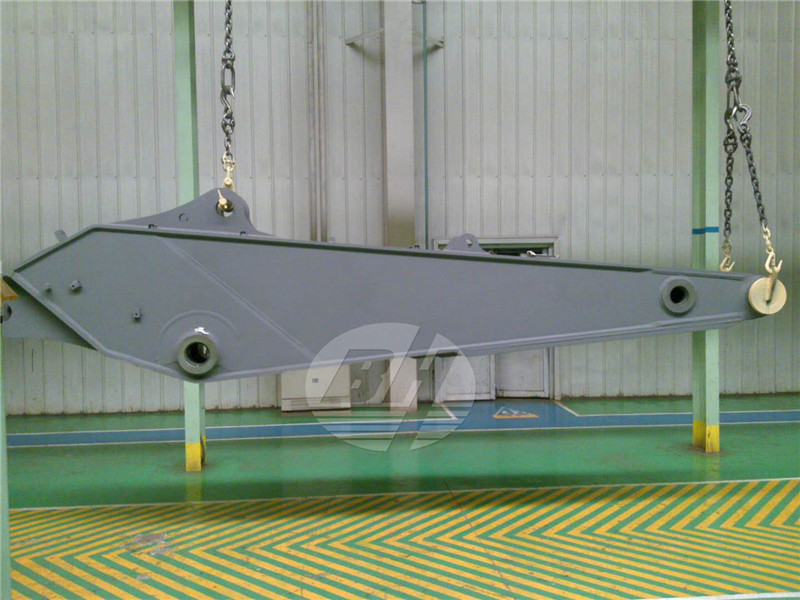

Tunnel type shot blasting machine profile

It also can named hook pass through type shot blasting machine

This type of cleaning machine is suitable for the surface cleaning of large and medium-sized castings, forgings and structural parts in casting, construction, chemical, motor, machine tool and other industries.

Tunnel type shot blasting machine application

We use shot blasting technology to achieve the purpose of derusting and strengthening, because shot blasting is still the most economical and reliable method in the world. Compared with other

cleaning technologies, shot blasting has the following advantages:

Improve the fatigue resistance of mechanical products and metal components

Eliminate stress concentration

Extend its service life

Optimizing the surface state of the workpiece

Greatly improve the cleaning efficiency

Reduce the labor intensity of cleaning up

Reduce environmental pollution

This type of equipment is widely used in machinery manufacturing, engineering machinery, mining machinery, pressure vessels, automobiles, ships and other industries to improve the appearance quality and surface process status of its product parts.

Tunnel type shot blasting machine working principle

Mechanical sand surface treatment is the use of high-speed rotation of the impeller, to clean the surface of work piece.

after a very short period of time (usually 5-7 minutes), to complete the entire cleaning process.

Technical parameters Hook pass through type shot blasting machine

Tunnel type shot blasting machine main specification

| Item | QT3720 | QT3740 | QT3760 | QT37100 |

| Size of cleaning workpiece (mm) | 10000*600*1200 | 10000*1500*1600 | 10000*1500*2000 | 1000*2000*2500 |

| Turbine | QBH036 | QBH036 | QBH036 | QBH036 |

| Abrasive flow rate(kgs) | 4*250 | 8*180 | 8*180 | 12*250 |

| Power of turbine (kw) | 4*15 | 8*11 | 8*11 | 12*15 |

| Total power(kw) | 95 | 140 | 140 | 260 |

Tunnel type shot blasting machine function

QT37 hook type shot blasting machine is a new type of equipment independently developed by our company. It is a non-standard product specially designed by our company according to customer requirements. It has the following advantages:

The use of 4-12 large-scale shot blasting volume and high shot speed of the international fourth-generation belt centrifugal shot blasting machine, significantly improves cleaning efficiency and obtains satisfactory cleaning quality.

The simulated projectile diagram (including the determination of the model, number and spatial arrangement of the projectile) is drawn in three dimensions using computer-aided design (CAD). The selection and arrangement of the projectile is more reasonable. The utilization rate and labor productivity of the projectile are improved, the cleaning effect is ensured, and the wear of the chamber body guard plate is reduced. The design of the equipment is completely done with CAD.

Separator adopts BE-type full-curtain type separator technology of American Pan Bangen Company, and the separation effect is good.

Workpiece cleaning adopts hook-hanging mobile pass-through cleaning, which has a high degree of automation and greatly reduces the labor intensity of workers.

Tunnel type shot blasting machine advantages:

1. Compact structure, small size, no bottom pit, easy to load and unload, wide range of transportation, installation and debugging

2. Large shot blasting volume and high projectile speed, significantly improving the cleaning efficiency and obtaining satisfactory cleaning quality

3. The blasting device adopts curved blades, which has good cleaning effect and strong energy saving

4. Full-curtain separator, good separation effect, improves the life of the wearing parts of the shot blaster

5. The hook has the functions of self-lifting, walking, indoor rotation, etc. to ensure the cleaning quality

6. Pneumatic gate, pneumatic pill supply, energy saving and labor saving

7. The sealing structure around the gate is good, to ensure that no steel sand flew out, to ensure the safety of staff and the sanitary environment

Product detail pictures:

Related Product Guide:

Using a complete scientific top quality management program, great high-quality and fantastic religion, we win great track record and occupied this area for One of Hottest for Hot Selling Abrator Turn Table Shot Blasting Cleaning Equipment Machine - Tunnel type shot blasting machine profile – Binhai Jincheng , The product will supply to all over the world, such as: Guinea, Oslo, Saudi Arabia, With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!