Low MOQ for Shot Blasting Machine For Cleaning Surface - Shot blasting machine for Steel track with large specification – Binhai Jincheng

Low MOQ for Shot Blasting Machine For Cleaning Surface - Shot blasting machine for Steel track with large specification – Binhai Jincheng Detail:

Product Description

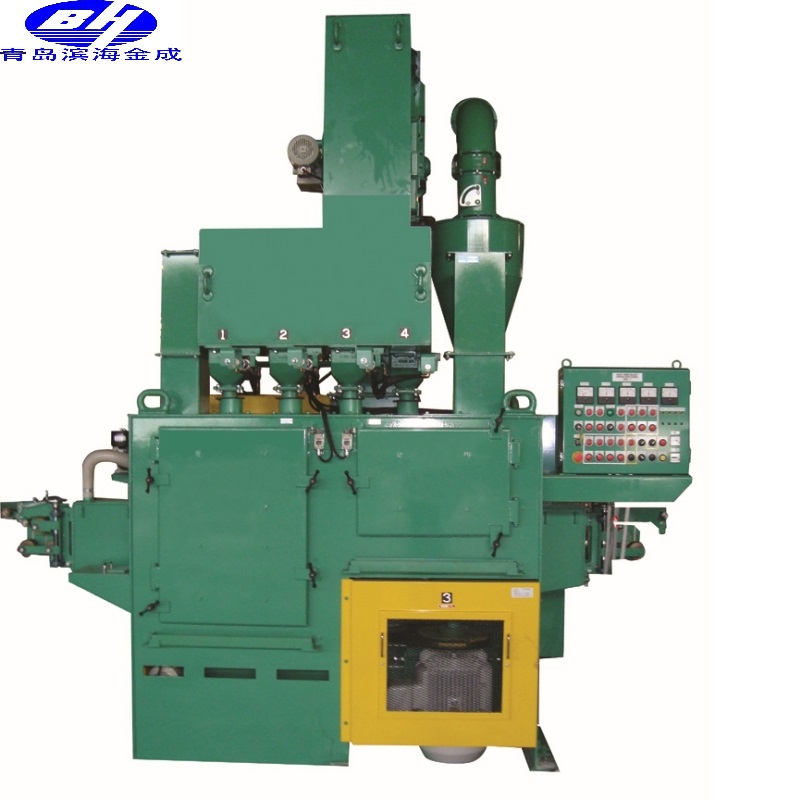

This crawler type shot blasting machine is one of the standard series of cleaning equipment. It can be used to clean casting, forging and welding parts, and remove the sand and oxide scale on the surface of the workpiece. Due to the good protective measures of the machine, the good performance of the shot blasting machine, and the reasonable structure of the projectile circulation system, satisfactory results can also be obtained for materials and workpieces that are difficult to clean.

The machine can also be used to clean workpieces that are easy to rotate and fall, non-brittle parts that are not easy to break, and castings with a deep core.

Range of application

steel and cast iron foundries, die-casting of light alloys, thermal treatments, pressure die-casting, galvanic treatments, small size and big weight part and so on.

Main components of steel track type shot blasting machine.

This machine is composed of cleaning room, crawler drive, projectile circulation system, shot blasting device, dust removal system and electrical system

Product features

15GN 28GN steel tumble belt blast machine with steel mill designed to allow high production levels, at particularly low costs, of small and medium-sized items, in intermittent loads; their characteristics include a continuous conveyor belt, in special anti-abrasive steel plates, for the rotation of the pieces during blasting.

Automatic discharge, with reversal of direction of the conveyor belt.

Technical parameters

| No. | Item/Specification | 15GN | 28GN |

| 1.turbine | Turbine power | 30kw | 22kw*2pcs |

| Rotation speed | 2250-2900r/min | 2250-2900r/min | |

| Abrasive flow rate | 480kg/min | 360kg/min*2 | |

| Abrasive speed | 80-90m/s | 80-90m/s | |

| 2.Belt drive | End disk diameter | 1092mm | 1245mm |

| End disk space | 1245mm | 1778mm | |

| Feeding volume | 0.5m3 | 0.79m3 | |

| Loading weight per time | 1500 kg/drum | 3000kg/drum | |

| Max. single part weight | 250kg | 360kg | |

| Belt speed | 5.6m/min | 3.6m/min | |

| 3. power | Screw conveyor | 1.1kw | 3kw |

| Feeder | 3kw | 7.5kw | |

| Steel tracks motor power | 2.2kw | 3kw | |

| elevator | 2.2kw | 4kw | |

| Door lift/down | 1.1kw | 3kw | |

| turbine | 30kw | 44kw | |

| Dust collector | 11kw | 11kw |

The advantages of steel track shot blasting machine:

1.Torsion-resistant, high-rigidity fuselage shell.

2. Reasonable chain drive system and geometric motion principle, which ensures that the firm, overlapping track shoes always maintain a smooth connection.

3.High-quality casting chain link, after precise processing and hardening treatment.

4.After being hardened and ground, the chain pin still has the smallest tolerance gap after long-term load operation.

Advanced man-machine environment, easy to maintain:

(1) All bearings are installed outside the shot blasting room.

(2) All the fixing parts of the protective plate are installed outside the shot blasting room, which is easy to disassemble and ensure that the fixing parts are not damaged by the shot blasting flow.

(3) The upper and lower positions of the material door are limited by limit switches for limit control, and there are safety limit switches for monitoring.

(4) The material door adopts electric opening and closing door, the structure is compact, and the wire rope is wound by the reducer, which is convenient to use, safe and reliable.

Company information

1.30 years focus on shot blasting machine

2.professional R&D team

3.CE,ISO9001,BV,SGS certificates

4.High quality and competitive price

5.Considerate after-sale service and technical assistance

6.World class quality machine

7.OEM&ODM are acceptable

8.Deliver time within 5days for standard equipment

9.Respond you within 24hours

10.Free charge for installation, training and debugging

11.WIN-WIN partner

12.12months warranty

13. six big workshops

14.exported USA, Russia, Australian, Iraq, Vietnam, Africa, Chile, Korea, Malaysia……

15.factory total area is 220000m2

Product detail pictures:

Related Product Guide:

we can offer high quality products, competitive price and best customer service. Our destination is "You come here with difficulty and we give you a smile to take away" for Low MOQ for Shot Blasting Machine For Cleaning Surface - Shot blasting machine for Steel track with large specification – Binhai Jincheng , The product will supply to all over the world, such as: Angola, Albania, Thailand, We win many reliable customers by rich experience, advanced equipments, skilled teams, strict quality control and best service. We can guarantee all our products. Customers' benefit and satisfaction are always our biggest goal. Please contact us. Give us a chance, give you a surprise.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!