High Quality for Shot Blasting Machine Gas Cylinders - BHLP series Mobile–Portable type Shot Blasting Machine – Binhai Jincheng

High Quality for Shot Blasting Machine Gas Cylinders - BHLP series Mobile–Portable type Shot Blasting Machine – Binhai Jincheng Detail:

1.Overview:

Pavers shot blasting machine is a special equipment for pavers roughing which is dedicated designed by our company for the pavers processing industry.

It is mainly used to increase the friction coefficient of the pavers surface and improve the surface decoration effect.

After being processed by pavers shot blasting machine, the surface of the pavers will show an effect similar to that of litchi surface.

It is widely used in the fields of marble wall hanging and anti-skid on the ground.

For the moment, more and more ground paving prefers the rough surface, has a board market prospect.

According to the production classification, it belongs to Q69 Series Pass-Through type shot blasting machine.

2.Working principle:

During the cleaning process, the frequency conversion motor driven the roller table to send the work-piece into the shot area of the cleaning room.

The impact of the powerful and dense steel shot in the coordinate direction makes the corroded skin and dirt on the pavers drop rapidly, and the stone obtains a smooth surface with a certain roughness.

The steel shot and rust falling on the top surface of the work-piece are transported to the projectile circulation through the screw conveyor.

Under the operating of the shot blasting machine, the surface of the pavers will quickly erodes the flat surface into a three-dimensional litchi surface and fire surface.

This processing method has a fast processing speed, usually each team can handling more than 2000 square meters (according to 8 hours), it is very popular with customers.

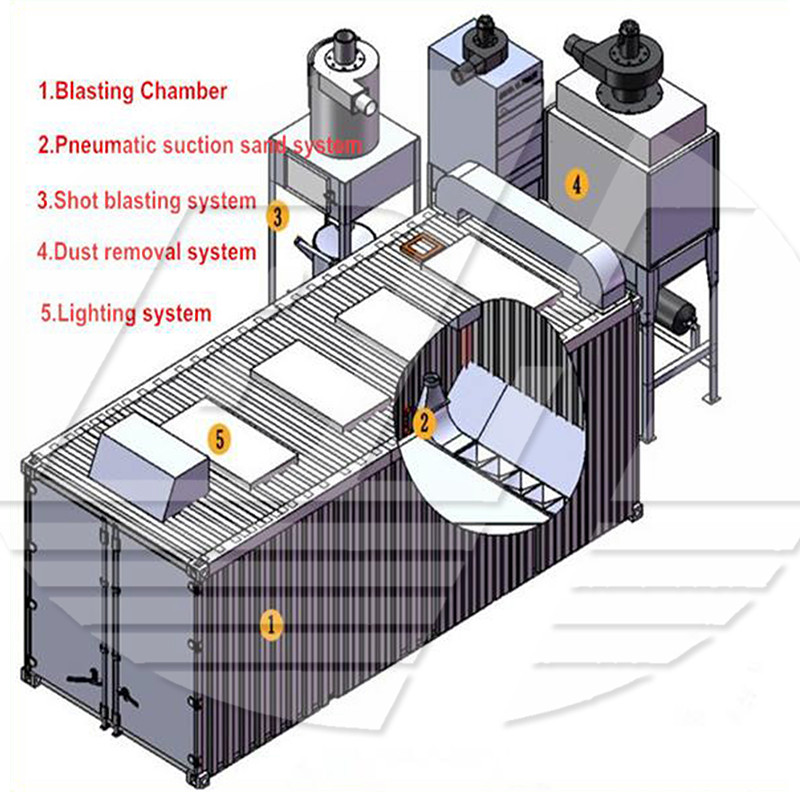

3.Composition:

It consists of the following components: Shot blasting room, Front sealed chamber, Rear sealed chamber, Feeding in roller table, Sending out roller table, Longitudinal screw conveyor, horizontal screw conveyor, Bucket elevator, Separator, Platform, Roller in blasting chamber, Dust removal system, Electrical system, Steel shot distribution system, Screw conveyor, etc.,

4.Main features:

Simulated shot diagram (including the determination of the model, number and spatial arrangement of the impeller head) and all drawings of the shot blasting machine are completely drawn by CAD. And after many times of practical experience optimize, to achieve a more perfect shot effect.

The body of the cleaning room is made of high-quality Q235A steel plate (thickness 8-10mm). The inner wall is lined with 10mm thick “Rolled Mn13” protective plate which has the reputation of “the best protective plate” and “lifetime” , and adopts“Block type” protective plate layout.

The Impeller Head is based on fully absorbing Shinto. Japan technology, and after continuously optimized, independently designed and manufactured by ourselves, with the feature of large blasting volume and high shot speed.

Adopting advanced “BE” type full-curtain Separator, and this separator was independently developed by our company on the basis of completely absorbed the technology of Swiss GEORGE FISCHER DISA (GIFA) and American Pangborn company, with perfect separation effect.

Steel shot control system: The shot gate valve controlled by the cylinder is used to control the supply of the steel shot at a long distance, We can through adjust the bolts on the shot controller to obtain the required shot blasting amount. This technology is independently developed by our company.

5.After sale service:

The product warranty period is one year.

During the warranty period, all the faults and damaged parts of the electrical control and mechanical parts due to normal use will be repaired and replaced (except for wearing parts).

During the warranty period, the after-sales service implements an “instant” response.

Our company ’s after-sales service office will be provided technical service in time within 48 hours after receiving the user ’s notification.

6.RAQ:

In order to provide the best solutions for your products, please let us know the answers of the following questions:

1.What’s the products which you want to treatment? Had better show us your products.

2.If there are many types of products need to be treated, What’s the biggest size of the work-piece? Length * width * height?

3.What’s the weight of the biggest work-piece?

4.What’s the production efficiency do you want?

5.Any other special requirements of the machines?

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for High Quality for Shot Blasting Machine Gas Cylinders - BHLP series Mobile–Portable type Shot Blasting Machine – Binhai Jincheng , The product will supply to all over the world, such as: Swedish, Portugal, Jakarta, We are adhering to the philosophy of "attracting customers with the best products and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.