China Gold Supplier for Treating Equipments Shot Blast Wheel - Mobile type Shot Blasting Machine for Paves – Binhai Jincheng

China Gold Supplier for Treating Equipments Shot Blast Wheel - Mobile type Shot Blasting Machine for Paves – Binhai Jincheng Detail:

working principle:

The Floor shot blasting machine also called “movable type” shot blasting machine. It is the shot blasting machine ejects the shot material (steel shot or sand) at a high speed and a certain angle onto the working surface through a mechanical method.

The shot material fully impacts the working surface to achieve the rough surface and remove residues.

At the same time, the negative pressure generated by the dust collector will clean the pellets and the cleaned impurity dust etc. after the airflow, the intact pellets will be automatically recycled, and the impurities and dust will fall into the dust collection box.

Advantages:

High degree of automation, can climb and walk, and the used shot materials can be recycled.

No pollution, this kind of movable type shot blasting machine is equipped with a dust collector, and the dust can be recovered for purification treatment.

Low energy consumption, will greatly reduce the loss cost for enterprises every year.

More convenient, walkable, reasonable and compact design, small footprint, can be taken to the construction site at any time.

Low investment, the investment capital is one-tenth of the traditional investment.

High efficiency.For example, just 550 type, it can clean 260㎡ per hour, SA2.5 level or above.

Application:

Environmentally friendly products specially developed for various road construction and maintenance, can be dust-free, pollution-free, and the pellets can be automatically recycled during construction operations.

It can be widely used for waterproofing and roughening of concrete bridge deck; cleaning and roughening of asphalt pavement to increase surface roughness; restoration of anti-skid performance of pavement, tunnel and bridge; clearing of asphalt pavement; cleaning of marking line; Anti-corrosion coating treatment; airport road glue and line removal.

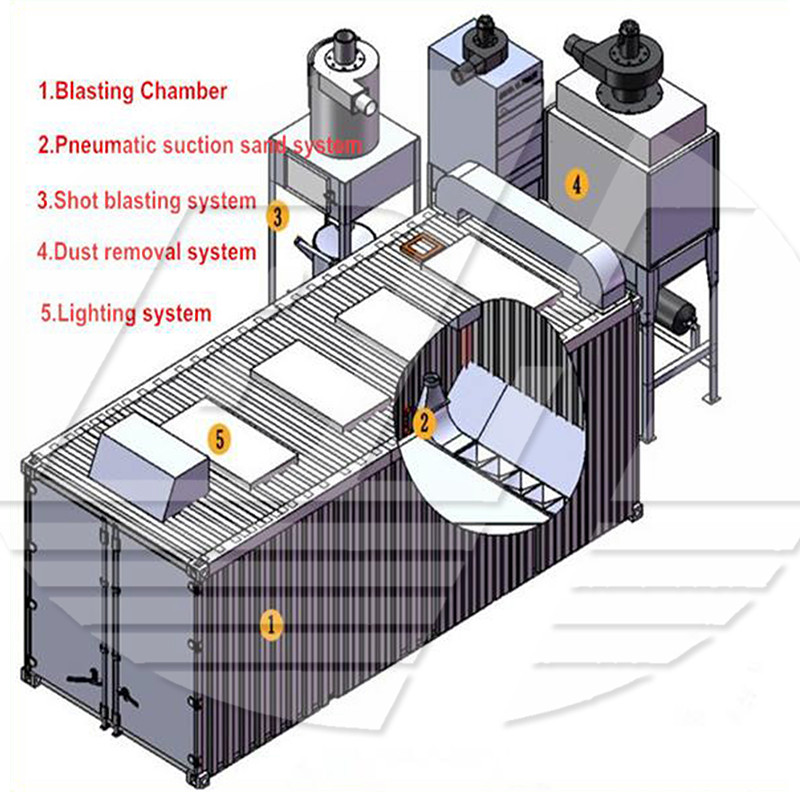

Main components:

Motor, soft starter, frequency converter, imported high-speed bearings, etc .;

Wear-resistant materials are used for the relevant parts of the shot blasting chamber to ensure the service life of the shot blasting chamber.

The wearing parts such as Impeller heads and directional sleeves are precision cast with wear-resistant materials, and the life is close to imported parts.

Equipped with steel shot collecting trolley, steel shot or granular steel can be recovered in one second. And this trolley doesn’t need power consumption. (using magnet)

Main technical parameters:

| Name | Parameter | Unit |

| Working width | 550 | mm |

| Blasting efficiency (concrete) | 300 | m2 |

| Rated power | 23 | KW (380V/450V;50/60 HZ;63A) |

| Weight | 640 | kg |

| Dimension | 1940*720*1100 | mm (L*W*H) |

| Steel shot consumption | 100 | g/m2 |

| Walking speed | 0.5-25 | m/min |

| Walking mode | Speed regulation | Automatic walking |

| Diameter of the impeller wheel | 200 | mm |

RAQ:

How to choose one set movable type shot blasting machine?

What’s the purpose of using this machine?

What’s the working width do we need? Such as: 270mm/550mm/more?

What’s the degree of the automation? Manual or automatic?

Product detail pictures:

Related Product Guide:

We are also focusing on improving the stuff management and QC system so that we could keep great advantage in the fiercely-competitive business for China Gold Supplier for Treating Equipments Shot Blast Wheel - Mobile type Shot Blasting Machine for Paves – Binhai Jincheng , The product will supply to all over the world, such as: Estonia, Nigeria, The Swiss, In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a professional engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We are your best choice.

A good manufacturers, we have cooperated twice, good quality and good service attitude.