Function of catenary type shot blasting machine

Function of catenary type shot blasting machine

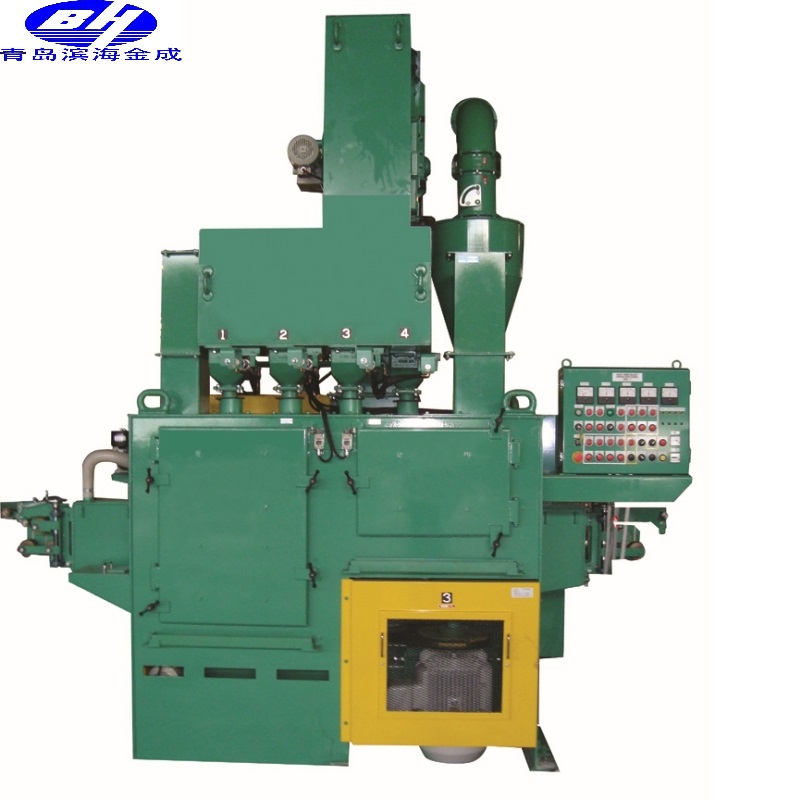

Q38,Q48,Q58 series catenary stepping shot blasting machine used to remove castings, forgings, structural parts such as the workpiece surface sand, scale, rust and so on. The surface of the workpiece appears metallic luster, and castings surface defects exposed to eliminate the stress within the workpiece, the surface roughness to Ra12.5 requirements GB6060.5 requirements, in line with national JB / T8355-96 Sa2.5 level.

Main model specification of catenary type shot blasting machine

| Type | Workpiece cleaning volume(mm) | Abrassive flow rate (kg/min) |

| Q383 | Φ 600 x 1400 | 4 x 260 |

| Q384 | Φ 800 x 1500 | 6 x 260 |

| Q385 | Φ 900 x 1400 | 4 x 260 |

| Q4810 | Φ 1000 x 1500 | 6 x 260 |

| parameter | Q583 | Q585 | Q5810 | Q588 | |

| size of cleaning work piece | mm | 800 x1500 | 800 x1200 | 1300 x2800 | 550 x2200 |

| number of hook | Set | 2 | 4 | 6 | 4 |

| number of blaster | kg | 4 | 6 | 6 | 4 |

| abrasive flow rate | kg/min | 4 x250 | 6 x360 | 6 x330 | 4 x480 |

| power of blaster | kw | 4 x15 | 6 x22 | 6x22 | 4 x22 |

| max.weight of Crane loads | kg | 300 | 500 | 1000 | 800 |

| capacity per hook | h | 40 | 55 | 50 | 30 |

| size of cleaning chamber | mm | 3062 x1800x2800 | 8500 x1800x3885 | 8500 x2300x4800 | 6800 x2600x3325 |

| total air volume | m³/h | 15000 | 18000 | 18000 | 17200 |

| total power | kw | 74.5 | 186.85 | 186.85 | 121.05 |

Catenary type shot blasting machine Application :

Clean Iron Casting

Clean Steel casting

Clean Forging

Clean Stamping parts

Clean LPG cylinder

Other type metal with very big cleaning efficiency

Catenary type shot blasting machine feature

Improve fatigue resistance and anti-fatigue

Remove the sand of metal surface

Increase service life

Remove metal rust

Remove metal surface oxide skin

Make the surface show metal luster.

Improve adhesive force before painting

Remove the internal stress

Main Features

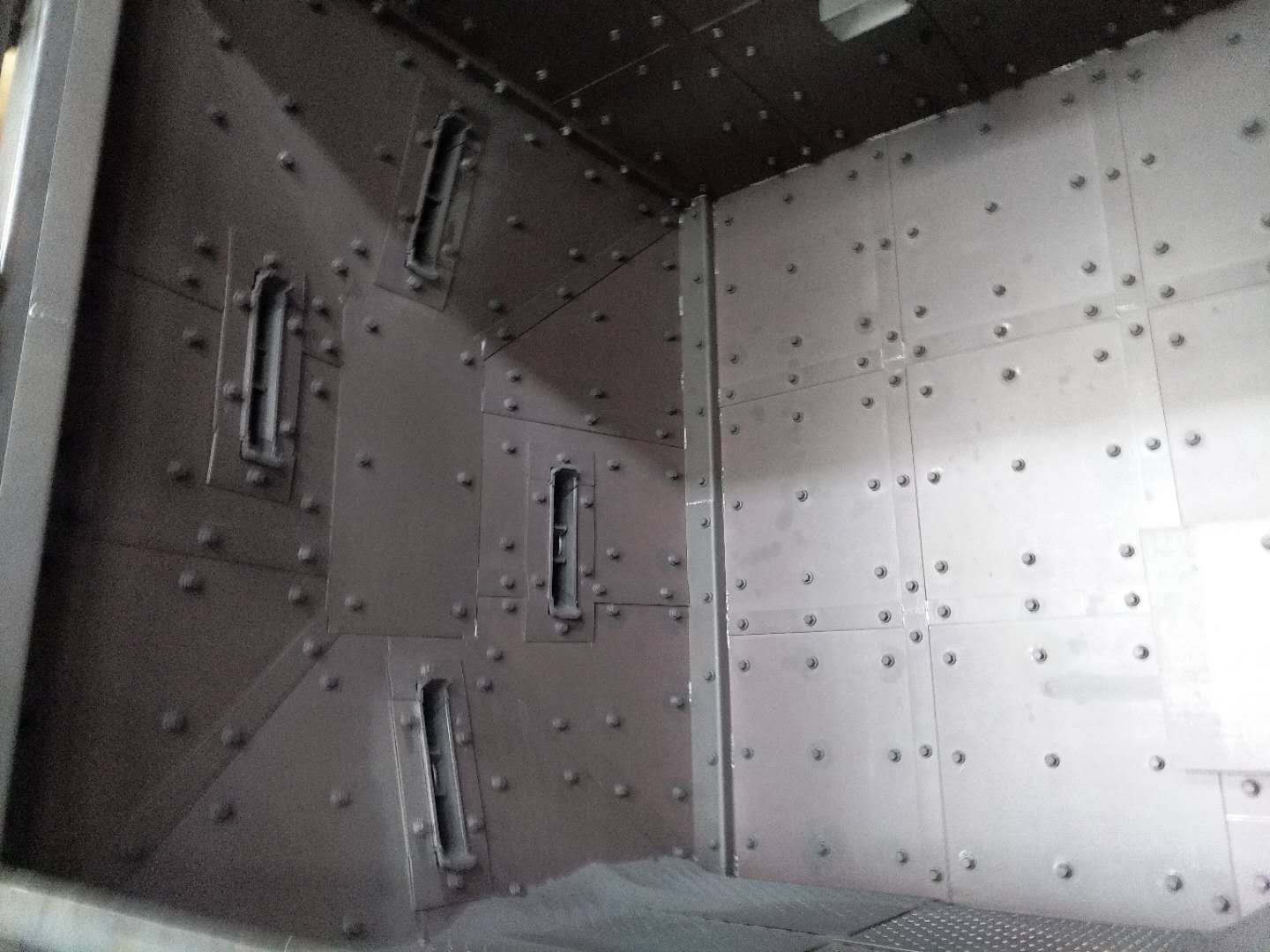

1)Rolling manganese 13 protect board,8000-10000 hour longer life time.

2) Straight or Y shape track conveyor,loading capacity 500-50000kg

3) High cleaning speed and saving labor.

4)turbine spare parts are all high chrome

5)compact and strong structure

6)dust concentration less than 80mg/m3

7)can use ABB motor,SEW reducer,SKF bearing

8)package:wooden box for control cabinet

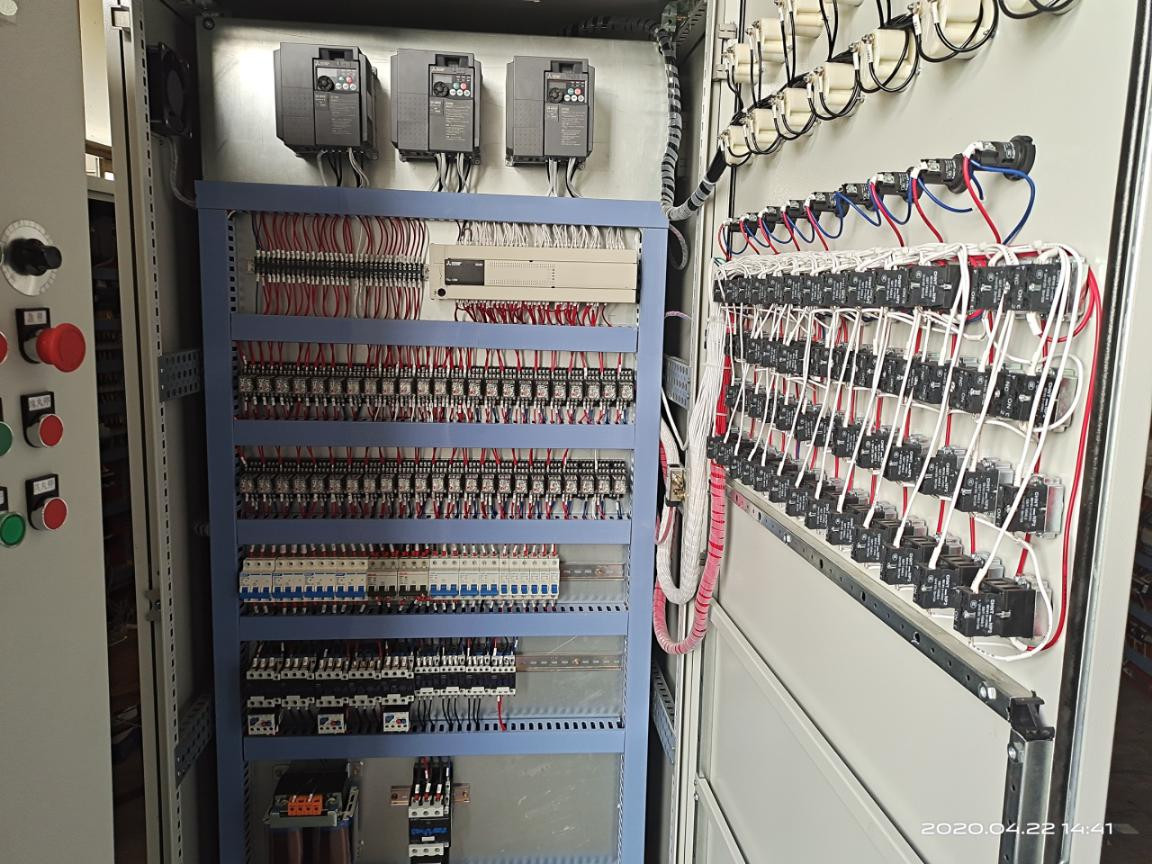

9)PLC(Siemens or Omron or Mitsubishi brand) control system, and adjust parameter and security

10)The projectile circulation system uses an active monitoring device. When some parts are not running smoothly or are stuck, it will actively alarm and notify the faulty parts, which is convenient for targeted repair

11)Workpieces can be cleaned while walking, or walking after cleaning, etc., with a high degree of initiative, greatly reducing the labor intensity of workers

10)delivery time:within 5days for standard type,others usually 15-60 working days

What documents we supply?

1.Instruction manual is in Chinese and English. It contents

Lay-out drawing ,Lay out drawing will be provided within one month after the contract is in active.

Operation, maintenance and lubricating instructions

Electrical schemes

List of recommended spare parts with the prices

Documentation of standard components

2.Bill of loading,picking list,certificate of origin

3.Engineer can go to your place help for installation